Sapphire Optics

Coating Service

HYT Sapphire Optics Co,.Ltd. currently has more than 2,000 varieties and specifications, mainly sapphire optical windows, infrared windows, filters, lenses, plunger rods, one-way valves, G5-level high-precision ruby balls, styli, gem micropores, gem bearings, gemstones Nozzles, special-shaped gems, precision ceramics and other components are widely used in laser technology, LED, infrared optics, medical equipment, fluid control, fiber optic communications, precision measurement, mechanical automation, analytical instruments, printing and inkjet printing, high-pressure water jets and other fields.

HYT SAPPHIRE OPTICS is professional in coating design and service. We can do all kinds of coatings including filter coating, Anti Reflection Coating, High Reflection Coating, Filter Coating, Beamsplitter Coating, Metallic Coating etc.

Optical Coating

Optical coating refers to the process of coating a layer (or multiple layers) of metal (or dielectric) thin films on the surface of optical parts. The purpose of coating on the surface of optical parts is to reduce or increase light reflection, beam splitting, color separation, light filtering, polarization and other requirements. Commonly used coating methods include vacuum coating (a type of physical coating) and chemical coating.

Coating Classification

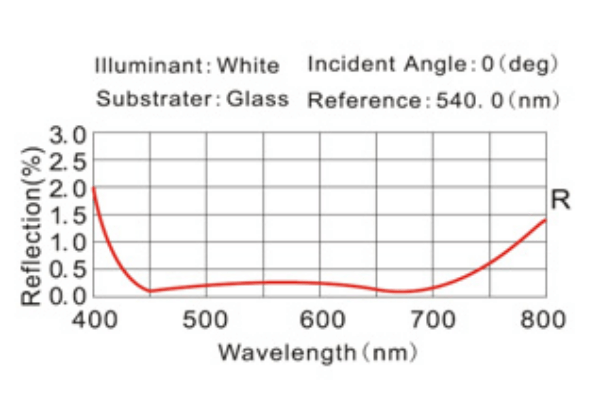

Anti Reflection Coating

AR Coating is the most widely used optical film, which can reduce the reflectivity of the optical surface and increase its transmittance. For a single wavelength, the theoretical reflectance can be reduced to zero, and the transmittance is 100%; for the visible spectrum, the reflectance can be reduced to 0.5%, or even lower, to ensure that a complex system composed of multiple lenses has sufficient High transmittance and extremely low stray light. None of the modern optical devices are without anti-reflection treatment. Due to its extremely low reflectivity and bright surface color, glasses in modern people's daily life are generally coated with anti-reflection coatings.

Anti Reflection Coating

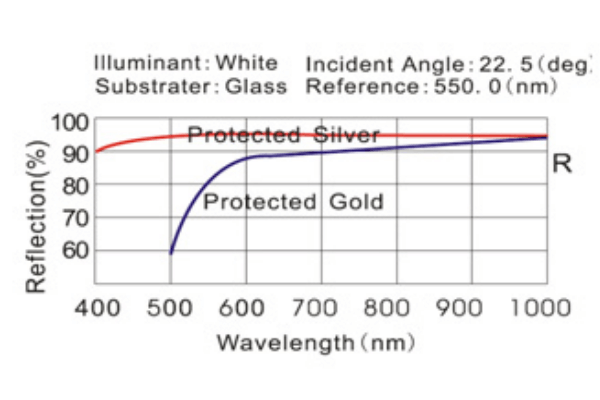

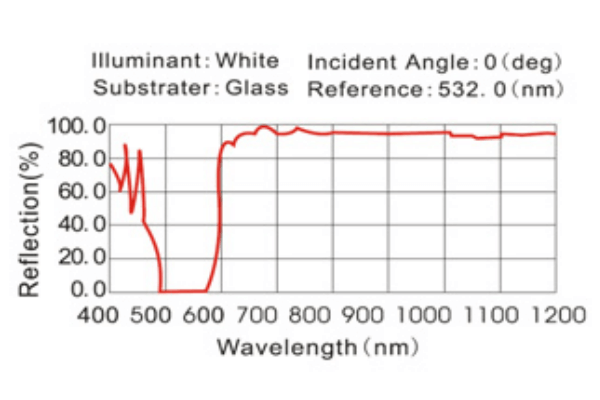

High Reflection Coating

HR Coating Can reflect most of the incident light energy back. When the dielectric film stack is selected, because the loss of the optical film is extremely low, as the number of film layers continues to increase, its reflectivity can continue to increase (close to 100%). Such highly reflective coatings are essential both in the manufacture of lasers and in laser applications. The film may serve as a reflector,beamsplitter,neutral density filter or electromagnetic interference filter.The most common metal coating as for mirror is Al, Ag, Au, Cr, etc.

High Reflection Coating

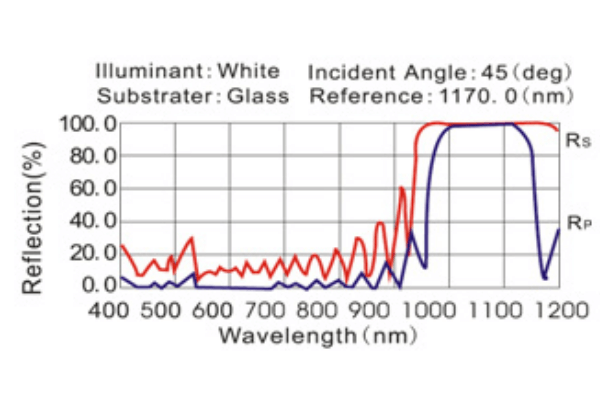

Partial Reflective Coating

A dielectric coating consisting of alternating layers of quarter-wave film of a higher refractive index and lower refractive index than the substrate. Such coatings can be made very specific to a reflected wavelength or, by varying the layers' thickness or film index, spread over a wide wavelength interval including high reflection coating(HR) and partial reflective coating(PR).

Partial Reflective Coating

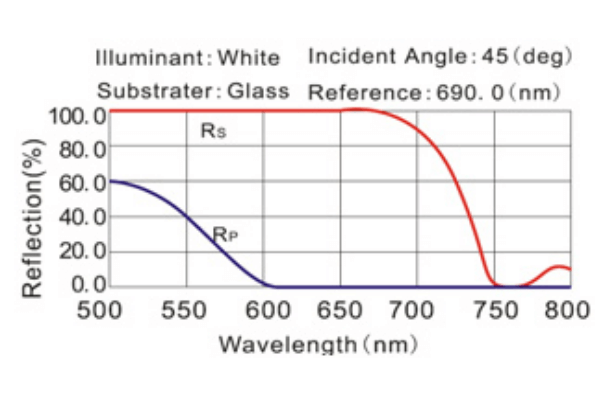

Beamsplitter Coating

An optical device for dividing a beam into two or more separate beams. A simple beamsplitter may be a very thin sheet of glass inserted in the beam at an angle to divert a portion of the beam in a different direction.A more sophisticated type consist of two right-angle prisms cemented together at their hypotenuse faces.The cemented face of one prism is coated ,before cementing,with a metallic or dielectric layer having the desired reflecting properties.

Beamsplitter Coating

Filter Coating

Optical Filters are used to selectively transmit or reject a wavelength or range of wavelengths. Optical Filters are used in applications such as fluorescence microscopy, spectroscopy, clinical chemistry, or machine vision inspection. Optical Filters are ideal for life science, imaging, industrial, or defense industries.

Filter Coating