Sapphire synthetically created through a process known as "crystal growth." Unlike other gemstones that are mined from the earth, sapphire is produced by placing aluminum oxide powder in specialized equipment and subjecting it to high temperatures in a vacuum environment.

The production of synthetic sapphire crystal predominantly relies on several advanced techniques, each offering unique advantages tailored to specific applications. Among these methods are the Kyropoulos method, the Stepanov Method (EFG), the Heat Exchanger Method (HEM), and the Czochralski process.

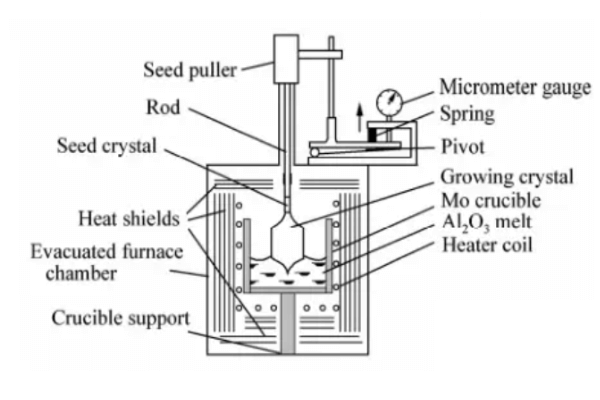

Kyropoulos method

Kyropoulos method (KY) involves melting aluminum oxide in a crucible, where a seed crystal is then submerged into the molten material. Through controlled cooling, a single crystal ingot forms around the seed, characterized by its high purity and low defect density. This method is favored for its ability to produce large, high-quality sapphire crystals suitable for LED substrates.

Kyropoulos method

Stepanov Method

Stepanov Method, also known as Edge-Defined Film-Fed Growth (EFG), employs a process where molten aluminum oxide is drawn through a capillary to form a thin film on a rotating substrate. As the crystal solidifies, a continuous ribbon of sapphire is formed, offering precise control over thickness and geometry. EFG is widely utilized in the production of sapphire sheets for applications such as windows and covers in aerospace and military sectors.

Edge-Defined Film-Fed Growth Method

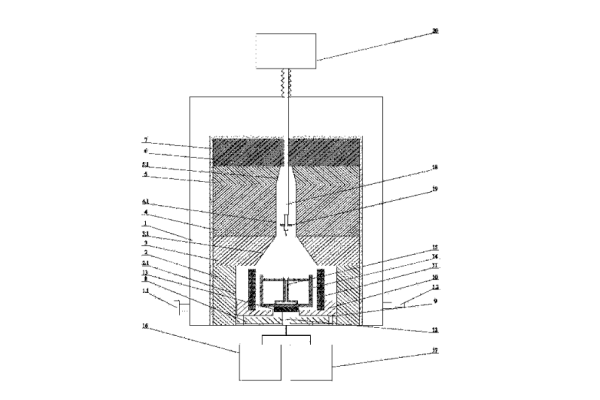

Heat Exchanger Method

Heat Exchanger Method (HEM), which entails heating aluminum oxide powder to its melting point within a crucible. A seed crystal is then introduced, initiating crystal growth as heat is exchanged to maintain optimal conditions. This method yields sapphire crystals with uniform structure and size, making them ideal for electronic components like smartphone screens.

Heat Exchanger Method

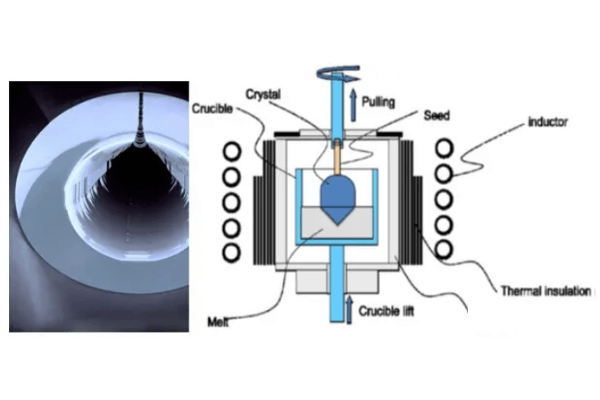

Czochralski process

Czochralski (Cr) process involves dipping a seed crystal into a molten aluminum oxide melt and slowly withdrawing it to allow crystal growth. This method produces high-quality sapphire ingots with tailored dopant concentrations, making them suitable for specialized applications in optics, lasers, and sensor technologies.

Czochralski Method

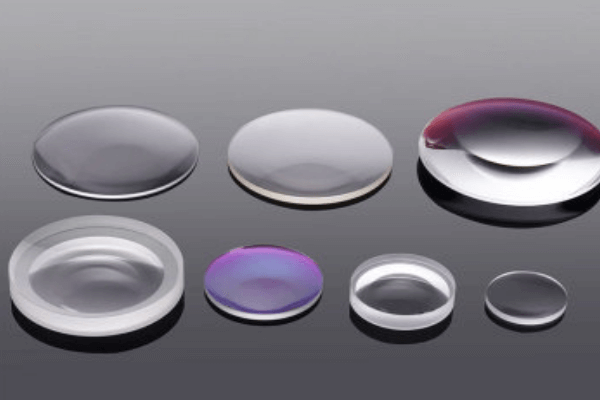

Specifications of Customed Shape Sapphire

| Material | Sapphire (Al2O3) |

|---|---|

| Diameter | 2mm ~ 600mm |

| Diameter Tolerance | +/-0.02 mm |

| Thickness | 0.1mm ~ 100mm |

| Thickness Tolerance | +/-0.01 mm |

| Surface Quality | 60/40, 40/20 or 20/10 S/D |

| Parallelism | 30 arc sec |

| Chamfer | < 0.2 mm x 45° |

| Coating | No coating or custom coating request |